Smart Factory Construction Project in Asia Pacific

On May 31, 2017, the first working day after Chinese traditional Dragon Boat Festival, Shanghai Epoch Information Technology - MARTINREA Asia Pacific Smart Factory Construction Project was officially launched in MARTINREA China Yuyao factory.

More than 20 people from project, marketing and technology departments of Shanghai Epoch Information Technology Co., Ltd. and MARTINREA Asia Pacific IT, manufacturing, R&D and process departments attended the project launch ceremony together; on the day of the ceremony, relevant personnel briefly communicated and exchanged ideas about the overall plan of the project.

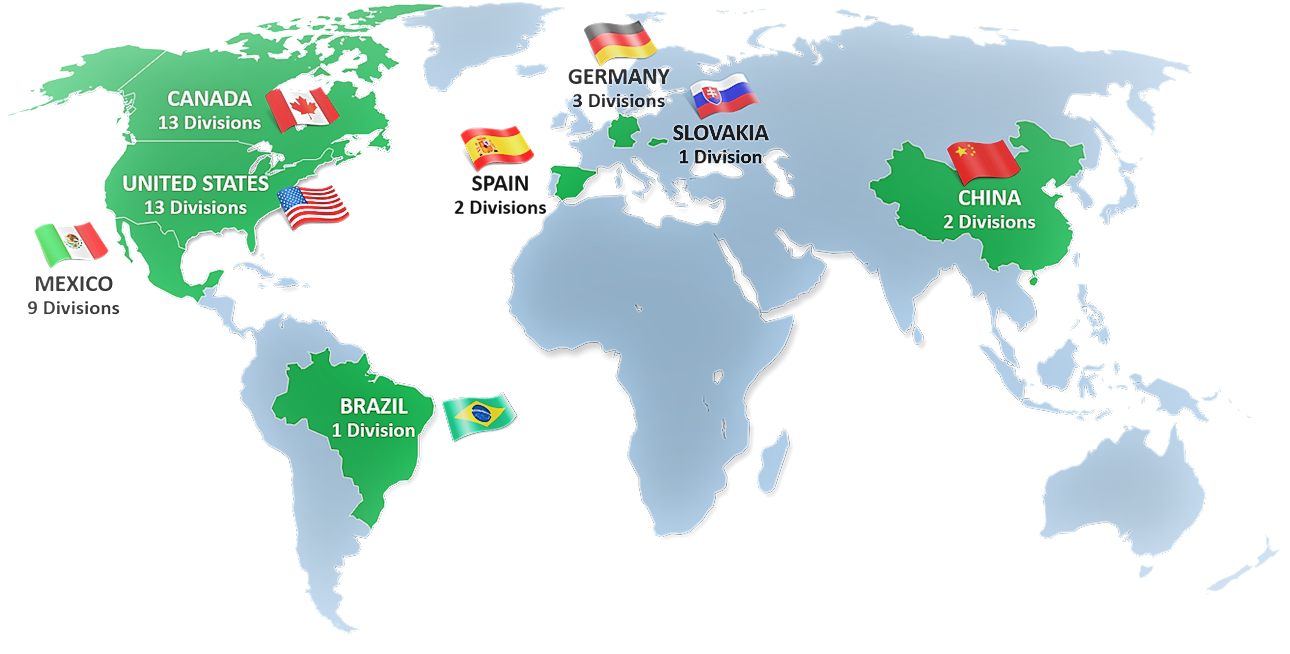

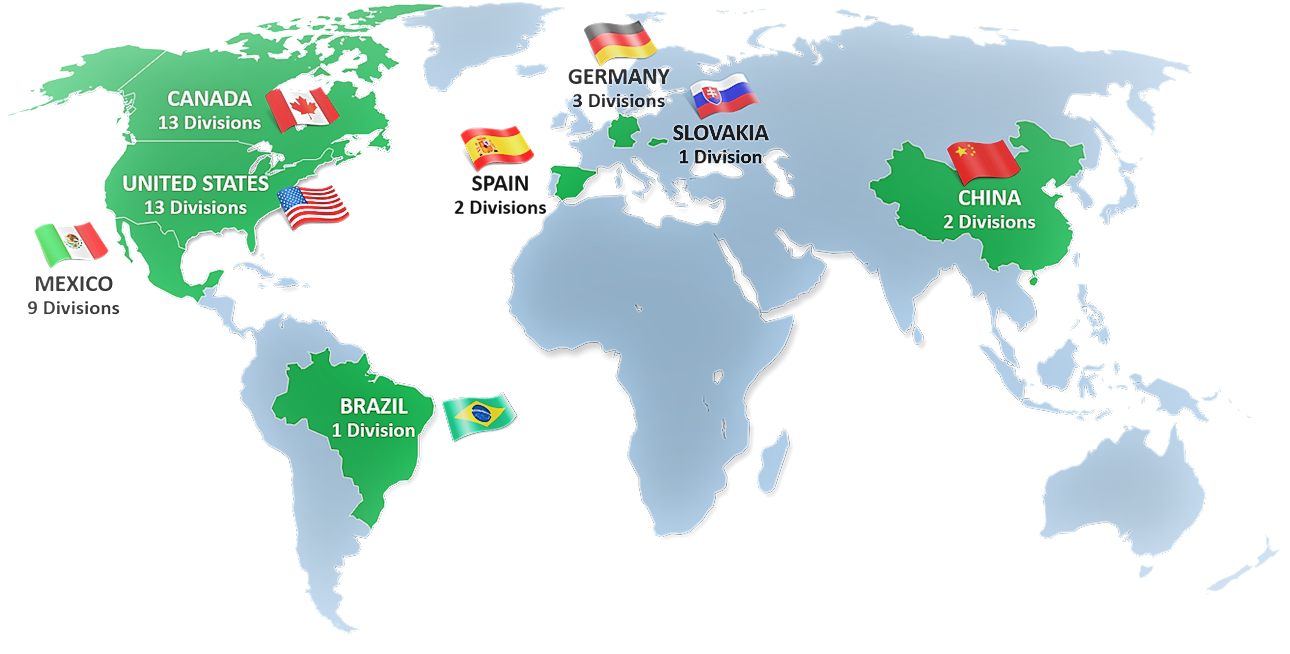

Headquartered in Canada, Matinria Group is an industry leader in the production of high quality automotive aluminum parts, assembly components and fluid control systems, and is a Tier 1 supplier to major automotive OEMs worldwide.

The Matinria Group is listed on the Toronto Stock Exchange and employs more than 14,000 people worldwide. The Yuyao plant is a subsidiary of Matinria Group, focusing on the production of high-end automotive aluminum alloy casting parts. Products include aluminum alloy brackets, aluminum alloy steering knuckles, and control arms. The products are supplied to customers including famous auto brands such as Cadillac and Jaguar Land Rover. In the global auto parts manufacturing industry, MARTINREA Group is ranked 58th overall.

MATINREA Group plants worldwide

MARTINREA Group's Asia Pacific plants began a year ago to search for a global supplier in the area of intelligent production management construction. Until the beginning of the New Year 2017, the final five suppliers competed fiercely in terms of product solutions, product application cases, system stability, team members' strength and global support capability. The reason why they finally chose to cooperate with Shanghai Epoch Information Technology Co., Ltd, the head of Asia Pacific IT of MATINREA Group finally gave the following explanation.

"MARTINREA Group is a global auto parts manufacturer, and the group company always insists on the business strategy of quality first and efficiency first. In the context of today's Industry 4.0 and China's integration of the two and smart manufacturing, the group attaches great importance to the construction of smart factories. In the early stage, we have done a thorough investigation in the industry, and it is also in the early investigation process that we found that Shanghai Epoch Information Technology iplant-MES is widely used in the field of auto parts production, including we have seen the overall application of Epoch Information Technology iplant-ACC system in the production sites of BorgWarner, ZF-Trinity, Magna and other companies. We were very impressed by the iplant-ACC system of Eppendorf Information Technology.

We finally chose to cooperate with Eppendorf for the following main reasons.

First, the product is mature and commercialized. Product functionality and stability can withstand years of market testing.

Second, the industry experience, deep understanding and research on process, management, quality and efficiency of global auto parts manufacturing industry, which can help us to improve MATINREA management.

iii. We recognize the strength of the team that can park information, including the comprehensive capabilities of project implementation, technology development and global support services.

The launch of MATINREA Asia Pacific project is another industry giant's manufacturing plant after Shanghai Epoch Information Technology's intelligent manufacturing data collection standard was adopted by the top 100 global auto parts manufacturers such as Trina, BorgWarner and Magna.

We will continue to provide total solutions for global auto parts manufacturers to collect and manage factory data.